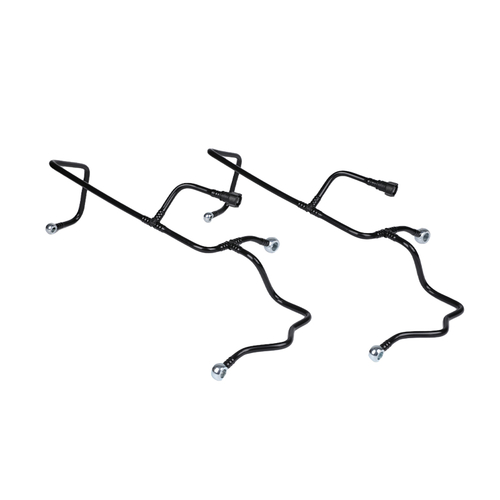

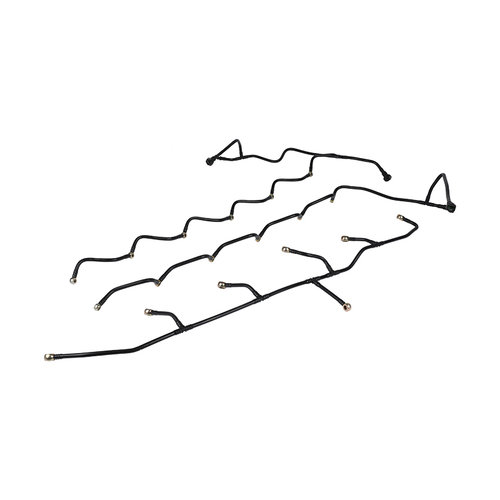

Advantages of Low-pressure tubing

Low-pressure tubing has a number of advantages, including:

Flexibility: Low-pressure tubing is typically made from flexible materials such as plastic or rubber, which makes it easy to bend and route around corners or obstacles. This makes it ideal for use in applications where space is limited or where the tubing needs to be routed through tight spaces.

Lightweight: Low-pressure tubing is often lightweight, which makes it easy to handle and install. This is particularly important in applications where large amounts of tubing are needed, such as in fluid or pneumatic systems.

Cost-effective: Low-pressure tubing is often a cost-effective solution for transporting fluids or gases. It is typically less expensive than high-pressure tubing or metal piping, which can help to reduce the overall cost of a project.

Corrosion-resistant: Low-pressure tubing made from certain materials, such as polyethylene or polypropylene, is resistant to corrosion from many chemicals and solvents. This makes it ideal for use in harsh environments or in applications where the tubing will be exposed to corrosive materials.

Easy to maintain: Low-pressure tubing is often easy to clean and maintain. It can be easily disconnected and reconnected for cleaning or maintenance, which can help to reduce downtime and increase productivity.

Wide range of sizes: Low-pressure tubing is available in a wide range of sizes to suit different applications. This makes it easy to find the right tubing for a particular application, whether it is transporting fluids, gases, or other materials.

Overall, the advantages of low-pressure tubing make it a popular choice in many industries and applications. Its flexibility, lightweight construction, and cost-effectiveness make it ideal for use in a wide range of applications, from fluid and pneumatic systems to medical and laboratory equipment.

Characteristic of Low-pressure tubingLow-pressure tubing is a type of tubing that is designed to transport fluids or gases at relatively low pressures. Here are some of the characteristics of low-pressure tubing:

Material: Low-pressure tubing can be made from a variety of materials, including plastic, rubber, and some metals. The choice of material will depend on the specific application, as different materials have different properties that make them more or less suitable for different uses.

Flexibility: Low-pressure tubing is often more flexible than high-pressure tubing, which makes it easier to bend and route around corners or obstacles. This is particularly important in applications where the tubing needs to be routed through tight spaces or around complex machinery.

Wall thickness: Low-pressure tubing typically has a relatively thin wall thickness, which allows for a greater internal diameter and smoother flow of fluid or gas. However, the thinner wall may make the tubing more susceptible to kinking or damage.

Pressure rating: Low-pressure tubing is designed to handle relatively low pressures, typically up to a few hundred psi. This makes it suitable for use in applications where high-pressure tubing is not necessary, such as in laboratory or medical equipment.

Temperature range: The temperature range for low-pressure tubing can vary depending on the material and construction of the tubing. Some materials may be more resistant to high or low temperatures, which may make them more suitable for use in extreme temperature conditions.

Chemical compatibility: Low-pressure tubing may be more susceptible to chemical degradation or corrosion than high-pressure tubing, as it may come into contact with more corrosive or aggressive fluids or gases. The chemical compatibility of the tubing material should be carefully considered when selecting tubing for a specific application.

Overall, low-pressure tubing has a number of characteristics that make it suitable for use in a wide range of applications. Its flexibility, thin wall, and moderate pressure rating make it ideal for use in laboratory, medical, and other applications where high-pressure tubing is not required. However, its lower pressure rating and thinner wall may limit its use in more demanding applications.

CN

CN EN

EN