Advantages of V Groove Pulley

V-groove pulleys have several advantages over other types of pulleys, including:

Improved Belt Traction: The V-shaped groove on the pulley provides better traction for the belt, reducing the risk of slippage. This means that V-groove pulleys are better suited for applications that require higher torque or power transmission.

Reduced Wear and Tear: The V-groove design also reduces the wear and tear on the belt, compared to flat pulleys or other designs. This results in longer belt life and lower maintenance costs.

Improved Efficiency: V-groove pulleys are more efficient at transferring power from the driving shaft to the driven shaft, compared to other types of pulleys. This means that less energy is wasted in the transfer process, resulting in lower energy consumption and higher efficiency.

Better Alignment: The V-groove design helps to keep the belt centered on the pulley, reducing the risk of misalignment or belt damage. This is particularly important in high-speed applications or where there is a lot of vibration.

Versatility: V-groove pulleys can be used in a wide range of applications, from simple power transmission to complex machinery. They are available in a variety of sizes and materials, making them suitable for use in almost any industry.

Overall, V-groove pulleys are a reliable and efficient choice for many different applications, offering improved belt traction, reduced wear and tear, improved efficiency, better alignment, and versatility.

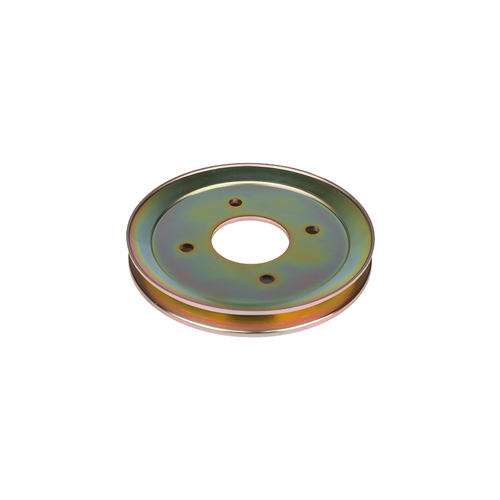

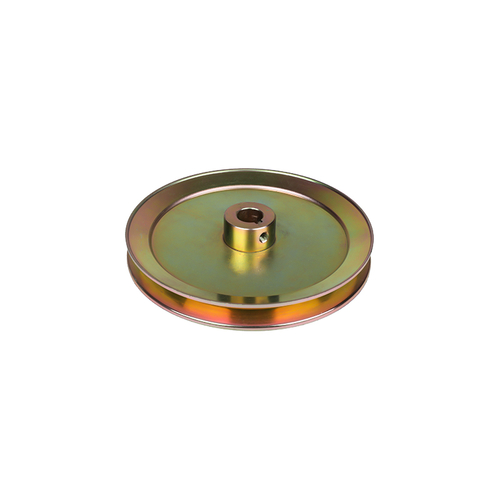

Characteristic of V Groove Pulley

Some of the key characteristics of

V-groove pulleys are:

V-shaped groove: The most distinctive characteristic of V-groove pulleys is the V-shaped groove around the circumference of the pulley. This groove is designed to provide better traction for the belt, reducing the risk of slippage and improving power transmission.

Material: V-groove pulleys are typically made of durable materials such as cast iron, steel, or aluminum, depending on the specific application requirements. The material used will depend on factors such as load, speed, and environmental conditions.

Size: V-groove pulleys come in a range of sizes, from small pulleys used in motors and other machinery to large pulleys used in heavy-duty applications. The size of the pulley will depend on factors such as the diameter and width of the belt, as well as the amount of power that needs to be transmitted.

The angle of the V-groove: The angle of the V-groove on the pulley can vary, depending on the specific application requirements. In general, the angle of the groove is designed to match the angle of the belt, which helps to improve traction and reduce wear.

Configuration: V-groove pulleys can be configured in a range of ways, depending on the specific application requirements. They can be used with a single belt or multiple belts and can be mounted in various orientations to accommodate different machinery designs.

Maintenance: V-groove pulleys are generally low-maintenance, but may require occasional cleaning and lubrication to ensure smooth operation and reduce wear.

Overall, V-groove pulleys are characterized by their distinctive V-shaped groove, their durable construction, their versatility in terms of size and configuration, and their low-maintenance design.

CN

CN EN

EN